Digitalisation

Digital transformation at Lamprell

Project Control Centre

Lamprell is evolving into a more connected, data-driven business. At the core of this transformation is our Project Control Centre, a centralised hub where the majority of our major digital initiatives converge. From here, we manage and monitor operations in real-time, integrating data from across our yards and project sites to enhance decision-making, improve visibility, and drive performance. Alongside these operational technologies, we’re also working with partners like Akselos to advance digital engineering and design insights. Through targeted digital solutions, we’re enhancing how we plan, execute, and deliver complex EPCI projects, focusing on improving safety, reducing inefficiencies, and building a smarter yard and workplace.

Engineering simulation with Akselos

As part of our long-term digital transformation, Lamprell partnered with Akselos to explore advanced simulation technology that enhances engineering and asset performance. Together, we developed a high-fidelity digital model of our proprietary 75-metre lifting frame, enabling deeper analysis of structural behaviour and maintenance needs. This collaboration has helped us identify cost-saving opportunities—such as potential steel weight reductions in offshore structures—while strengthening our ability to provide constructability input during the design phase. The insights gained are shaping how we approach future projects, with a focus on improving performance, reducing material use, and extending asset life.

Digital twin platform

Our digital twin platform gives us a real-time digital view of what’s happening on each project. It brings information together in one place, making it easier for teams to stay aligned, spot potential issues early, and keep things moving efficiently. It also helps us make better decisions during the project and when planning future work.

Advanced work pack system

This system digitises the creation and management of work packs, linking engineering data, material availability, and labour schedules. It reduces manual coordination and enables tablet-based progress tracking in the yard. The result is more efficient task planning, fewer delays, and clearer oversight of resources and performance.

SAIF-T: Smart safety systems

SAIF-T uses wearable tech, sensors, and AI to monitor worker wellbeing and enhance safety in the yard. Devices like smart bands, AI-enabled helmets, and cameras automatically flag risks and alert supervisors in real-time. By reducing reliance on manual checks, SAIF-T helps us respond faster and create safer working environments.

Smart Yard

Our smart yard initiative gives us a real-time digital view of our facilities, helping us track equipment, plan layouts, and use space more effectively. It’s designed to improve how we manage day-to-day operations and easily identify potential risks. While still being developed, it’s expected to play a big role in making our operations more streamlined as we grow.

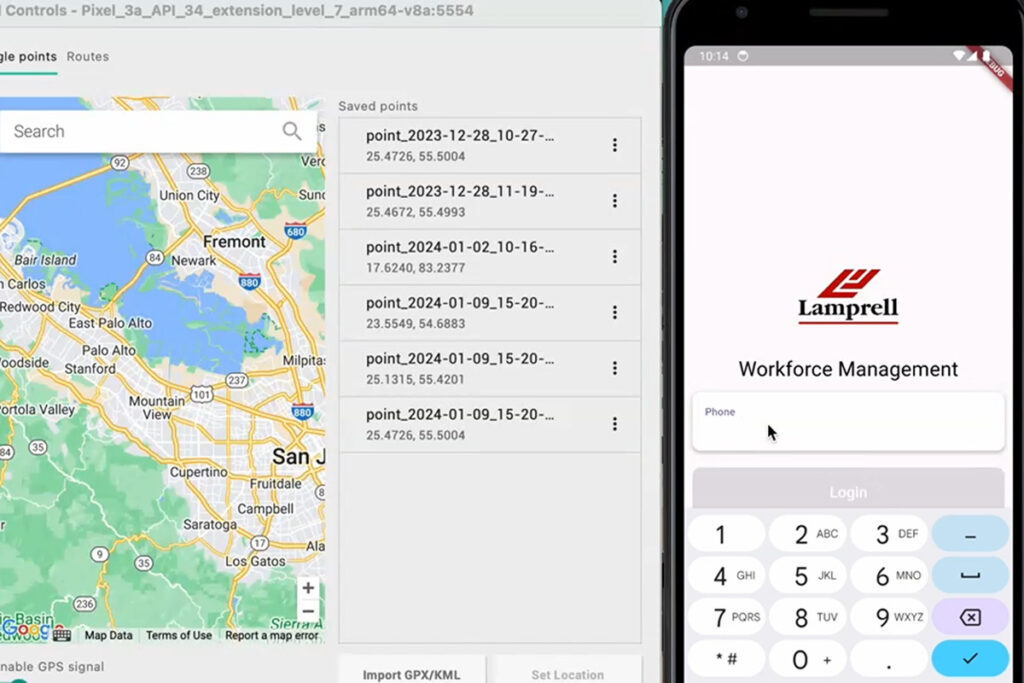

Mobile Workforce App

Our mobile app gives yard teams access to key services like attendance tracking, leave requests, and payslips directly from their smartphones. It’s replacing paper-based processes and improving day-to-day engagement. Future updates will expand its use across admin teams and field operations, such as inspections and reporting.

Looking ahead

We’re continuing to expand our digital capabilities with new tools under development, including AI-driven analytics, expanded mobile platforms, and deeper system integration. These efforts are shaping a more agile, efficient Lamprell that is ready to meet the evolving demands of the energy industry.