International Maritime Industries (IMI) is a joint venture established in Saudi Arabia that is being developed to advance maritime capabilities across rig building, vessel construction, maintenance, repair, and overhaul (MRO) services. Launched in 2017, IMI is strategically positioned within the King Salman International Complex for Maritime Industries and Services in Ras Al Khair. It is a cornerstone of Saudi Arabia’s Vision 2030 ambitions to diversify its economy and enhance local industry expertise.

IMI represents a collaborative partnership between Saudi Aramco, Lamprell, Hyundai Heavy Industries and Bahri, the National Shipping Company of Saudi Arabia. With state-of-the-art facilities, IMI is one of the largest shipyards globally, leveraging the combined expertise of its partners to deliver world-class maritime solutions to clients worldwide.

Lamprelltimes recently caught up with Darren MacDonald, Chief Operating Officer of MRO & New Build Offshore Rigs at IMI, to discuss the evolving relationship between Lamprell and IMI and the exciting future ahead as the Middle East’s biggest maritime facility becomes operational.

Lamprelltimes: Could you elaborate on the scale of the IMI yard and provide some details about its size and capacity?

Darren MacDonald: Certainly. The IMI yard spans approximately 12 million square meters, making it the largest full-service shipyard in the MENA region and the second largest globally. The quayside is over 9km long. The vast size of the whole facility will enable us to manage multiple large-scale projects simultaneously. There is nothing else like this happening globally, and being part of it is very fulfilling, albeit challenging.

Lamprelltimes: Can you explain how the IMI yard is structured, how it functions, and who manages it?

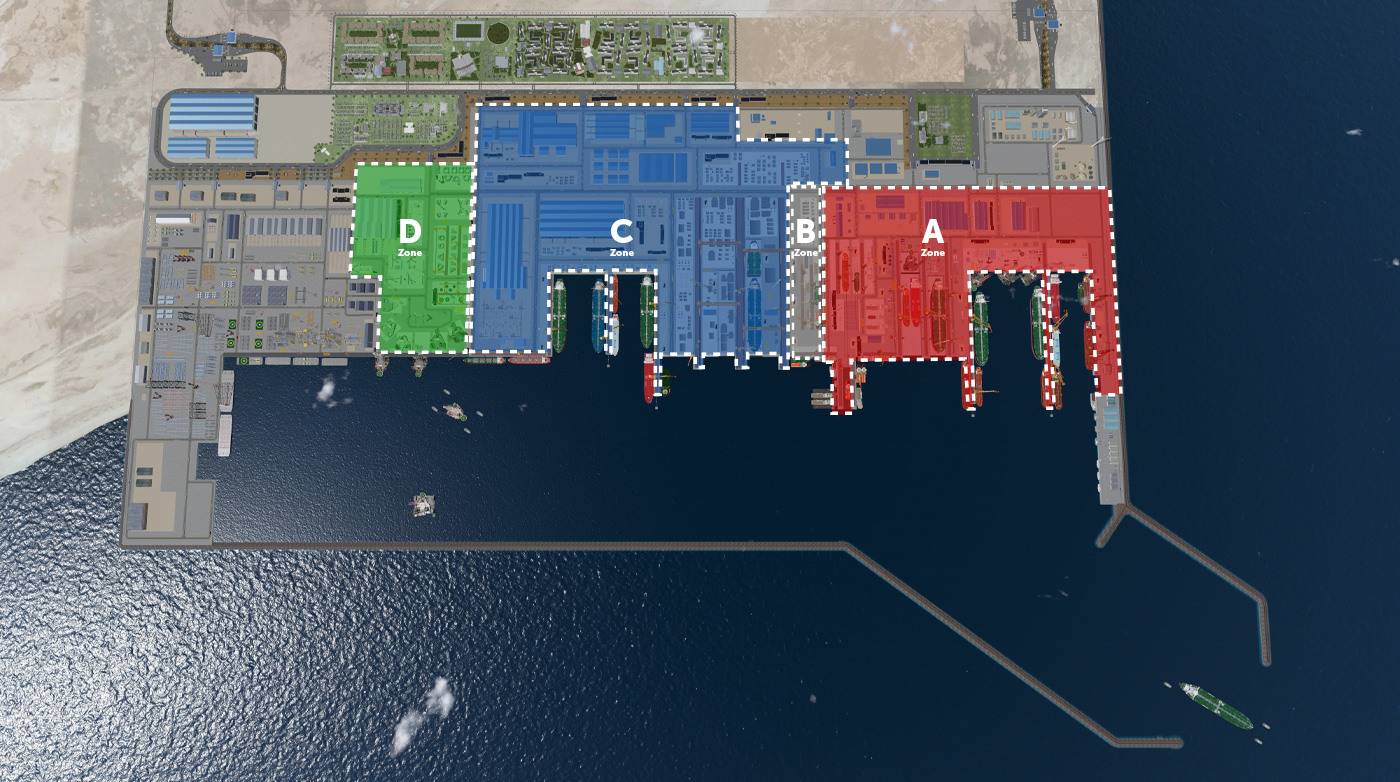

Darren MacDonald: The IMI yard is strategically divided into four primary operational zones, each tailored for specific maritime activities.

Zone A is dedicated to MRO services, with an impressive annual capacity for refurbishing and maintaining approximately 135 vessels, 115 Offshore Support Vessels (OSVs), and at least 15 rigs. Lamprell is actively involved in Zone A, leveraging its extensive experience in rig refurbishments.

Zone B is specifically designed for building new OSVs, with an annual production capacity of about 25 vessels. This area primarily focuses on serving clients requiring highly specialised offshore support crafts.

Zone C focuses on new vessel construction, accommodating larger-scale maritime projects. With an annual capacity of approximately 18 vessels, this zone benefits significantly from HHI’s expertise in vessel construction.

Zone D is dedicated exclusively to new-build rig and offshore projects and will deliver at least two rigs per year, with eight under various stages of construction simultaneously at peak. Lamprell plays a critical role here, delivering technical expertise and precision in rig construction projects. As IMI continues to develop its capabilities, some of the very high-tolerance rig components continue to be built in Lamprell’s UAE facility in Hamriyah. IMI will deploy a team to facilitate the transfer of this knowledge.

Lamprelltimes: How has Lamprell’s relationship with IMI evolved in recent years?

Darren Macdonald: The relationship has significantly strengthened into a robust technical partnership, and Lamprell is fully committed to IMI and KSA. Lamprell’s embedded senior professionals at IMI have been instrumental in sharing technical knowledge, processes and procedures, particularly in rig building and complex operations. It’s a great relationship that has grown in trust, scope, and mutual benefit.

Lamprelltimes: How many Lamprell employees are currently at IMI, and how have their roles evolved?

Darren MacDonald: We currently have around 12 senior professionals from Lamprell working with us. Their roles have organically evolved, enhancing their skills, increasing their understanding of joint ventures and partnerships, and navigating the broader business landscape, particularly in relation to Saudi Arabian business and Aramco’s operations.

Lamprelltimes: Tell us about Lamprell’s involvement in apprentice training.

Darren MacDonald: Our Lamprell team is actively involved in apprentice training, especially in rig construction. We’ve trained many apprentices in Hamriyah, and we now have hundreds more undergoing training within Lamprell’s designated areas of the IMI yard. They are involved in the new-build rig programme within Zone D and the Maintenance, Repair & Overhaul of many rigs and vessels within Zone A.

Lamprelltimes: Can you update us on IMI’s operational status and the projects that are underway, particularly those involving Lamprell in Zones A and D?

Darren MacDonald: IMI is progressing well. Although the yard was delayed by COVID, Zone D is fully operational, and much of Zone A is also, which is very exciting. The balance of Zone A’s facilities will be fully operational by midyear.

Lamprell’s dedicated Zone D is very active with significant projects running, including support for rig refurbishment and new builds. We have delivered over 70 rig refurbishment projects since we started operating in 2020 to several regional operators. We currently have three rigs in Zone D, and another six rigs and a few floaters in Zone A undergoing maintenance, with some warm stacked.

Zone A’s dry dock is commissioned, and we are testing operations there now and expect activity to ramp up significantly when they complete in the coming weeks.

In terms of new builds, we worked on Kingdom 1 and 2 alongside Lamprell and are currently constructing the third for client ARO Drilling. Rig 4 construction will also start very soon.

Lamprelltimes: Tell us more about the accommodation, recreational facilities, and overall lifestyle at IMI.

Darren MacDonald: IMI offers exceptional accommodation facilities, currently home to around 3,400 residents, with space to comfortably accommodate up to 14,000 men and women. Our residential area boasts great amenities, including modern sports fields, well-equipped gyms, and a wide array of recreational activities, such as cricket tournaments and football leagues, creating a vibrant and engaging community atmosphere.

Working at IMI provides unique and exciting career development opportunities for everyone involved. Expatriates have the chance to be part of establishing one of the largest and most ambitious maritime projects in the world, making significant contributions to a groundbreaking project recognised for its rapid development and global scale. This initiative is truly unprecedented, setting the stage for a lasting legacy that will become a permanent part of the Kingdom’s industrial landscape and aims to create 80,000 jobs.

Saudi nationals benefit substantially from IMI’s structured apprenticeship programmes, directly gaining valuable skills and knowledge from industry professionals with extensive experience, such as Lamprell. Increasing Saudi workforce participation directly supports employment growth, economic diversification, and the broader societal objectives outlined in Vision 2030—strengthening the nation’s future through education, skills development, and meaningful employment.

Lamprelltimes: Finally, how do you see the Lamprell-IMI relationship progressing?

Darren MacDonald: We expect deeper integration that will, in turn, support IMI’s rapid growth and determined efforts towards successful project deliveries. Lamprell is expanding its facilities within Saudi, which will enhance our joint operational synergies. The future is extremely promising, and we’re excited about the possibilities.

Thank you, Darren, for this insightful update on Lamprell and IMI’s collaborative journey.